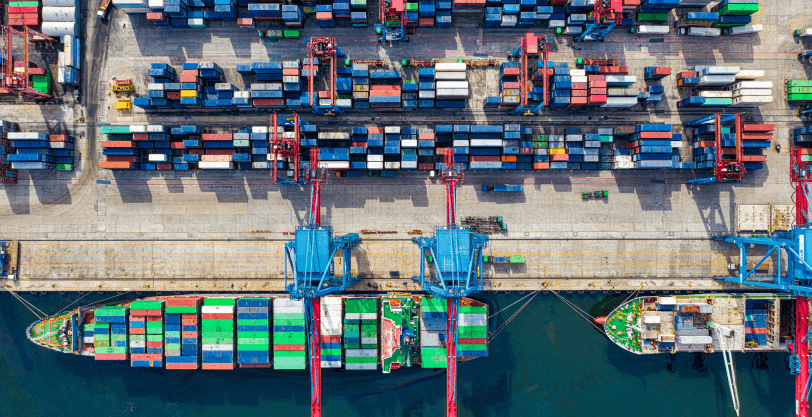

Globalization enabled the companies to source raw materials from across the world, and also expand their sales operations across the world. As a result, companies started sourcing cost-effective raw materials and finished goods across the borders, even though they have huge lead times and stock it in their inventories. This led to the rise of cost-effective manufacturing countries such as China, Bangladesh, India, etc. in the early Late 20th, and early 21st centuries and increased the prominence for process excellence to make their operations more efficient.

But recent pandemic events have made the companies rethink their operations, there was a sudden drop in demand, global supply chains were broken, and also pent-up demand for a few parts has made the manufacturing companies downsize their operations for the next couple of years. Few industries saw their inventories piling up at different parts of the value chain at the start of the pandemic, and as the pandemic eases companies ran out of inventories to meet the customer demand because of pent-up demand. Example: Automobile companies have a huge waiting period due to sudden pent-up demand and an increase in semi-conductor usage across the automobile industry. This is a wake-up call to most of the manufacturing companies to move from siloed operations towards a more goal-aligned, integrated, and collaborative sales and operations planning process. With sales and operations planning (S&OP), companies gain insight into their own financial data and demand trends within their market. This enables managers to optimize operations, from procurement to final shipments, saving inventory costs and mitigating risks.

S&OP requires collaboration with all business segments, including marketing, manufacturing, and finance, to create accurate, inclusive forecasts. By including all sectors, stakeholders gain the full picture of a company’s stability and longevity. To manage all of this companies need tools that can help in scenario planning, dynamic forecasting, collaborative and transparent system which are integrated into the ERP / CRM Systems. But most of the companies are still using traditional spreadsheets, which are non-collaborative and time-consuming to manage the sales and operations planning process.

Hence companies should prioritize implementing sales and operations planning technologies, which are integrated into the traditional ERP/CRM systems, flexible to create multiple scenarios elements, Analyse on multiple dimensions and Scalable to the different levels of the organization, and open to all. Effective sales and operations planning process

- Bridges the gap between strategy and execution

- Streamline the processes to collaborate and improve the efficiency of top management

- Enhances the customer service

- Lower the finished goods inventories

- Shorter customer order backlogs, hence shorter lead times

- Drives the right product, place, time, quantity, cost, and business performance

Anaplan is a cloud-based connected planning platform positioned to solve the new-age planning problems of organizations. Customers can implement their business processes on Anaplan and scale it very easily. It can be easily integrated into ERP / CRM Systems with inbuilt connectors across multiple ETL tools, which automates the process and reduces the chances of errors. Anaplan has inbuilt intelligence for augmenting predictive intelligence and ML algorithms.