One of the first attempt at Connected Business Planning was tried as an attempt to connect Material Requirement Planning with Sales departments planning. Planning prior to this was mostly a departmental activity isolated at that level, resulting in multiple disconnected plans for operations within same organizations. This led to inaccuracy in data as the assumptions of one team can’t be predicted by other teams which led to challenges like over production, underproduction, inventory mismanagement, logistics overloading, warehouse shortages etc.

S&OP is a business plan organizations use to connect the requirements of each department into a single workflow and develop a connected plan to achieve the company goals with best efficiency by balancing the demand projection and the supply capability. It helps in optimization of resources by better planning for every stage of the operations; ensures that all the business functions are coordinated to efficiently manage the process’s resource and time requirements which leads to optimization in production costs.

S&OP is a critical step of the broad-spectrum Supply Chain Planning and aims to get the Right Product to the Right Location at the Right Time at the Right Cost. S&OP development is a continuous process and during each cycle it is compared with AOP to keep its deliverables aligned with the organizational goals.

This continuous development method makes the plan more accurate and evolving in terms of assessing the mistakes, understanding the micro-events in the market, situational analysis of market for appropriate corrections and giving the managers enough control over the plan and execution to accurately gauge the outputs of their operations and intervene in strategic places to effectively optimize the key drivers to improve the results of execution and achieve the business goals more seamlessly.

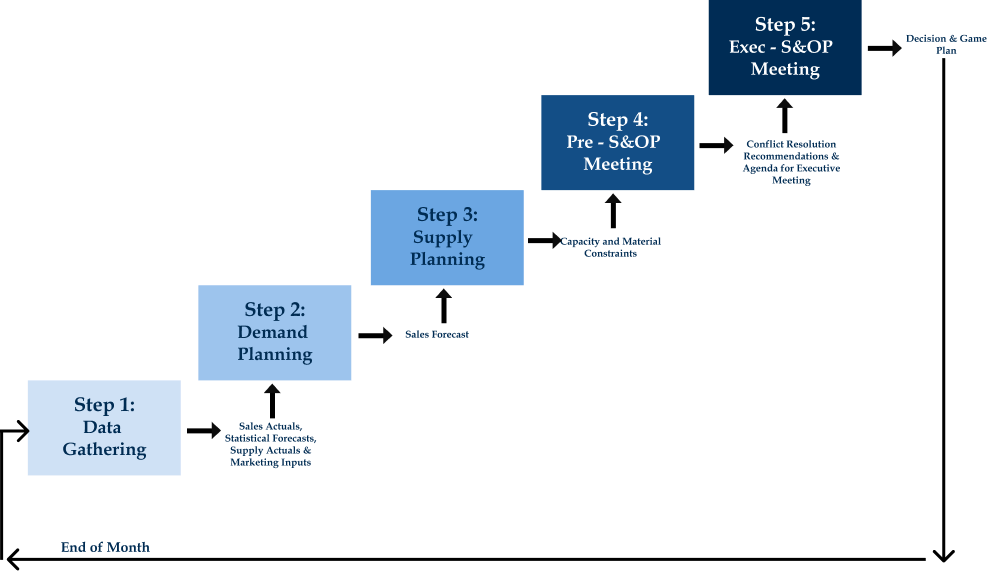

A classic S&OP is conducted in the followings six steps –

- Gather and Manage data – The first step of S&OP starts with data collection. All the historic product data for sales, marketing and production is collected from the relevant departments by the Demand Planner.

- Demand Plan – The Demand Planning Team analyses the collected data to create trends on company’s growth rate, sales seasonality and the market level research is used to understand the growth expected in market. Both put together draw up a demand forecast which is based on the demand that the organization can capture in the coming future.

- Supply Plan – The Supply Team works on the capability planning – They analyse the production capability for each product by accounting production rate with available resources, discounting any expected down times in the production and accounting for any other environmental variables.

- Pre- S&OP Meeting: The analysis of how much demand can be captured with existing production capability and what would be the cost to boost the capability for capturing the total demand is discussed with the finance team in this phase to understand and decide what approach is the company taking in the coming future period, a constrained approach to maximise the capability utilization and meet the possible demand or unconstrained approach to boost the capability and capture the maximum demand. The goal of this meeting is to produce the final demand and supply plan for coming 3months (rolling plan) and 15months (forecast plan).

- Executive S&OP Meeting: This final meeting is where the S&OP perfected after the Pre-S&OP meeting along with its analysis is shared with the CXOs, and approval is taken for both the rolling and the future plan.

For an S&OP to function properly the roles and responsibilities of the key stakeholders should be defined before the work starts. Once the planning begins for smooth flow of the process its very critical for team to know their part in the process and the expected output for the same. Proper analysis of the plan should be done for any weaknesses or potential problems. This is where, by the means of scenario planning or benchmarking the risk in the planning is mitigated. Contingencies for the same should be planned for along with appropriate identifiers to identify these problems in their preliminary stages for successful implementation of the contingency.

Major drivers for a successful S&OP implementation are –

- Timely Calendar – Ensure that the end-to-end process is recorded, and the plan v/s actual analysis is done for improving the accuracy of S&OP. All issues should be planned for with proper accountability and mitigation or contingency plans.

- Cross-Functional – S&OP is a phase of connected planning which works to ensure that multiple departments have same plan of action to reduce any miscommunication or management errors and thus cross functional participation is imperative to make it work successfully. This means teams should give open inputs and feedbacks whenever required and planning should be done to mitigate risks in every department’s operation.

- Executive Support – An effective S&OP requires higher management commitment. It’s an evolved process that requires many teams to work together for planning as well as execution; If the support from higher management in implementation or execution of S&OP lags then its effectiveness is deeply compromised as the teams don’t buy into the process with as much commitment.

Major advantages that the companies successfully implementing S&OP have over their competitors include –

- Optimized Supply Chain Activities – Predefined demand and supply plan helps in optimization of resources making it possible for the production team to utilize available resources in the best way and procure required resources within time with room to manage their sourcing for better cost advantage while meeting the delivery requirements. 5-10% Cost Reduction is observed in businesses by the means of labour cost, fixed cost, material cost and freight cost optimization.

- Better Inventory Management – Optimization of resources helps the organizations to define safety levels for inventory instead of keeping unlimited buffer stocks which helps in freeing up the working capital for the company. 20-30% Working Capital Improvement has been witnessed by the successful implementors of S&OP by the means of Inventory optimization and reduction in work-in-progress and warehouse goods.

- One Plan for All: Since a single plan drives the individual departmental goals and plans, all activities happen co-ordinately referring a single plan of action giving better efficiency to the execution. 2-4% Sales Growth has been seen in companies by improved service quality, better new product launches, increase in marketing effectiveness.