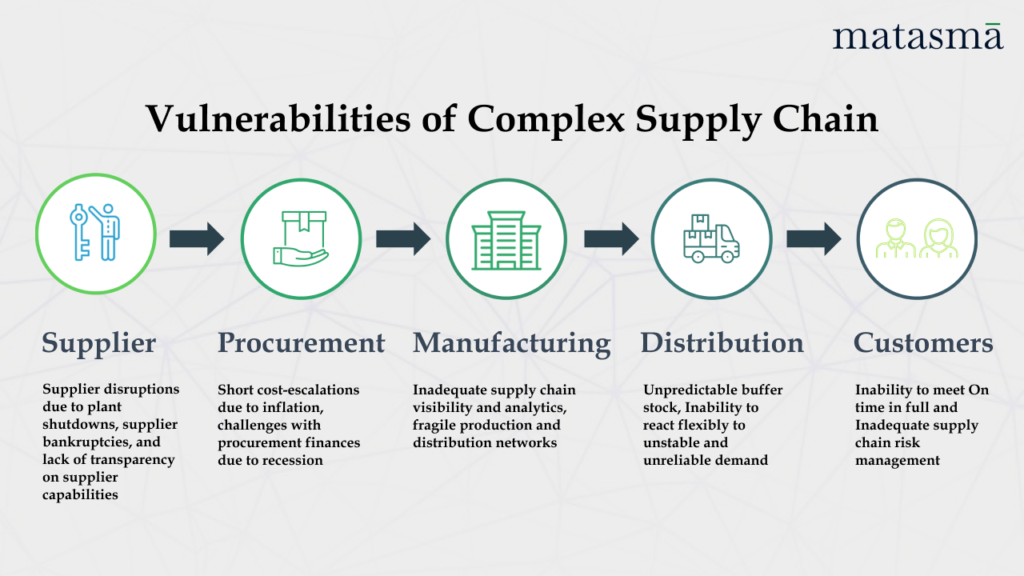

Supply Chain facilitates the journey of a product from production to the end customer. Effective supply chain planning helps to predict and plan for each process involved in this from raw material procurement through to post-sales service to the customer. It can help with demand estimation, procurement planning, production planning, material management, logistics streamlining, Inventory Planning, and more.

Over the past year, challenges of the VUCA (Volatility,

Uncertainty, Complexity, Ambiguity) world more visible than ever. It is

consistently inconsistent and thus the traditional practice of static supply

chain planning cannot account for the variations of the supply chain factors. Hence,

most organizations fail to take proactive steps to ensure business resilience.

When the COVID-19 pandemic disrupted supply chains across numerous major

industries worldwide and showed no signs of abating, most organizations had

limited vision in terms of how they should prepare to resume business

activities. This lack of clarity resulted from a confluence of uncertainties,

including when an effective vaccine might be widely available and what mandates

governments might implement to curb the coronavirus’s spread. Uncertainties can

never be eliminated but can always be better managed.

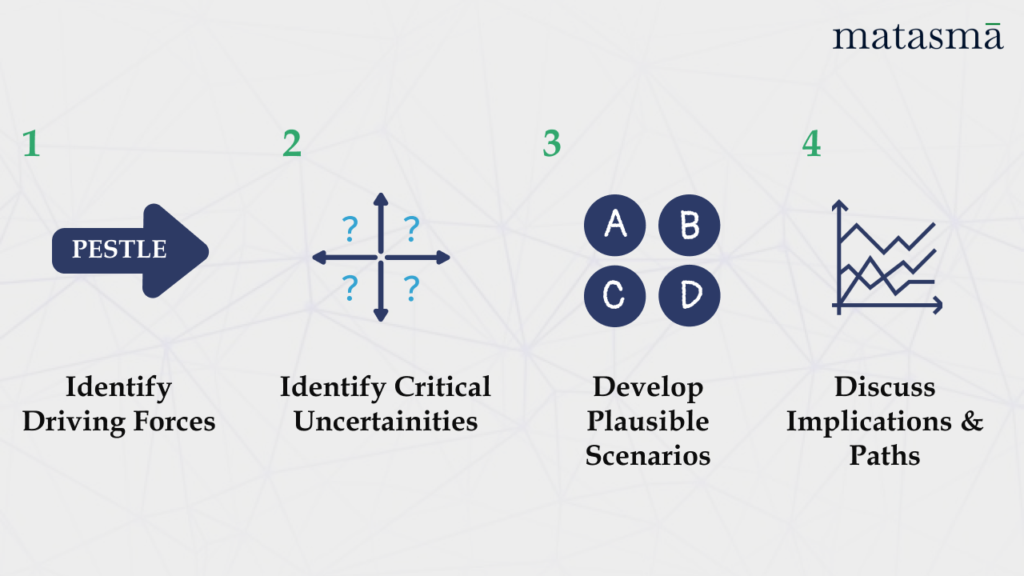

Scenario-based supply chain planning can help an

organization have a solid bedrock for its planning. It fits the requirements of

multiple processes in an uncertain market to devise a plan which can adapt to

the scenarios of the market. Scenario Planning helps businesses to deal with what-ifs,

by identifying the factors that affect the market specific to a business. Planning

is done for a specific time frame by considering the best or worst shift in the

market factors defined as Scenarios, and plans are laid accordingly.

Factor determination is a tailored task and needs to be specific to the organization and the market it caters to. Hence, it needs to be determined appropriately by subject matter experts. Post-determination scenarios are to be built by assessing the effect of the factors over the planning period – The Best & The Worst. This leads to the step of Planning where calculations need to be carried out for gauging the effects of these scenarios. Plans are then developed to match the organization’s goals in either scenario by tapping into assets or strategies that remain unaffected by the changes in the market for that scenario. This gives organizations an insight into what type of variability to expect in the coming time and decide about their growth or adjustment plan. It tells them what could be required as a resource or strategy.

Demand-side scenario planning can account for the economics of the consumer and the market, impacts of geo-political events, the decline in competitors or the emergence of other new ones, new product releases, or other variables of the market. The derivation of supply scenarios out of demand scenarios helps to evaluate and proactively manage risk. Apart from that, the implications of these scenarios on resources can be controlled. More specifically, the portion of demand covered, capacity impact, and inventory impact can be evaluated in terms of turnover, costs, and potential lost revenue. Finally, decisions can be made about inventory allocation, hiring, maintenance, shift patterns, or capacity expansion.

This ability to visualize different scenarios and their impact on various relevant factors, from demand planning, and supply planning to financial perspectives, promotes unbiased cross-functional and rapid decision-making at each planning level. It identifies risks and helps the cross-functional team to develop risk mitigation plans. It finally leads to a more structured discussion on the relevant supply chain parameters to make supply chain planning more flexible and resilient.